The Challenge

Martinswerk, a subsidiary of J.M. Huber Corporation and leading manufacturer of halogen-free flame retardants and other specialty chemical products, faced the challenge of optimizing its laboratory processes and integrating lab quality control more closely into its production processes. Until recently, data was stored in different, non-networked IT systems, which led to multiple inefficiencies and potential sources of error, including:

- No real-time access to quality analysis data

- Response times regarding the status and results of samples from the production process were too long.

- Too many additional work steps, such as transferring and linking data from different sources, which had to be carried out manually.

The lack of links between production data and laboratory data made it difficult to carry out detailed and timely analyses. It was also more difficult to obtain a quick overview of the samples' compliance with Martinswerk´s internal and customer specifications. Dr. Marc Steuber, LIMS project manager at Martinswerk, described the situation in the age of Industry 4.0 as “cumbersome, error-prone and simply uncool.”

The Solution

In collaboration with up to data GmbH, Martinswerk introduced Thermo Scientific´s modern laboratory information management system (LIMS) in March 2024. Up to data adapted the software to Martinswerk's requirements and processes and, in particular, programmed the interfaces to Martinswerk's ERP system (Oracle) and the production environment (Web-BDE Application). In addition, up to data provides support during and after the implementation.

The LIMS cloud-based solution enables:

- Seamless integration of laboratory measuring instruments

- Automated interface between data stored in production systems and laboratory systems as well as customer specifications in the ERP system

- Real-time access for operators to sample analysis results

- Efficient data analysis for production engineers

Project Progress

Under the leadership of the Quality Assurance team, laboratory, operations and IT colleagues worked closely together. The LIMS software was fully implemented and went live at the beginning of March 2024. Key to the project success was the comprehensive integration of different IT systems: LIMS was connected directly to measuring devices in the laboratory and interfaces were set up to the IT system which collects data from production processes (Web BDE Application) and to the ERP system (Oracle) which holds customer specifications for the products. Laboratory and Operations staff went through LIMS training sessions.

Convincing Benefits

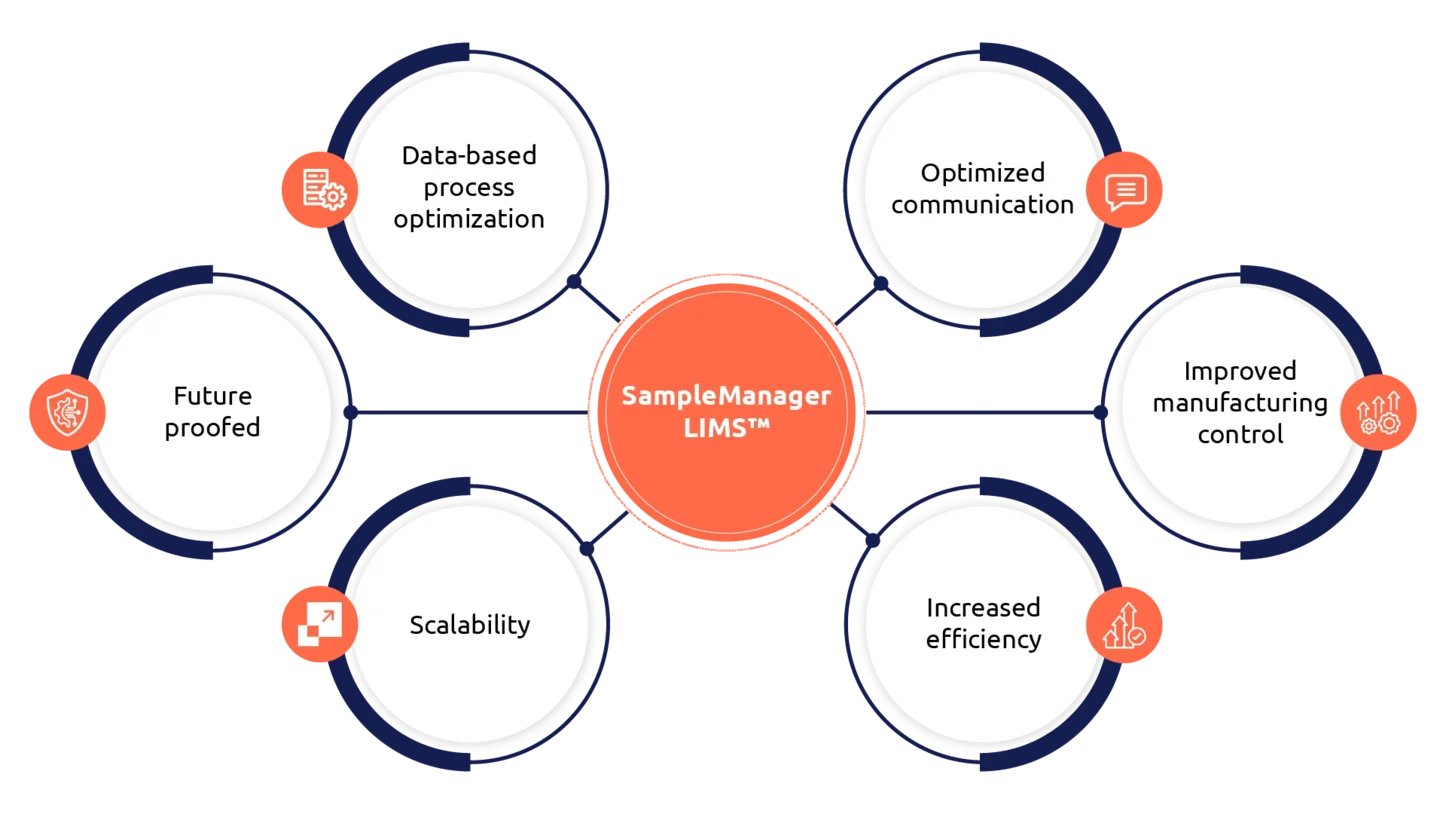

With the introduction of Thermo Scientific™ SampleManager™ LIMS, Martinswerk has made significant progress in digitalization at the interface between the laboratory and the production plants. This resulted in several positive effects:

Optimized Communication:

- Much more efficient exchange of information between the laboratory and the production plants

- Reduction of queries and waiting times

Improved Production Control:

- Operators can immediately react to sample analysis results

- Less non-conformity material and higher energy savings

- Increased Efficiency in the Laboratory and in the Production Processes from Day 1:

- Faster overview of sample conformity

- Automated daily analysis reports for plant managers

Scalability:

- Easy roll-out to additional sites and laboratories possible

- Flexible integration of new laboratory equipment and analysis methods

Future-proof:

- Important step towards Industry 4.0

- Basis for further steps toward digitalization and automation

Data-based Process Optimization:

- Detailed analyses for optimum control of production systems

- Supports teams to learn from each other

Quotes on the project

Nicole Müller, Senior Quality Manager at Martinswerk:

“LIMS ensures transparency and traceability of our quality analyses and ultimately enables better control of the production process.”

Dr. Marc Steuber, LIMS Project Manager and Analytical Chemist at Martinswerk:

“With the introduction of SampleManager LIMS™, Martinswerk is taking a key step towards Industry 4.0. We are very satisfied with the implementation and ongoing support from up to data.”

Dr. Martin Lohfink, LIMS project manager at up to data:

“The biggest challenge in the LIMS project with Martinswerk was the integration of the interfaces. The coordination of several departments and functions and the associated complexity of the requirements required a high degree of precision. The collaboration with Martinswerk is a complete success."

About Martinswerk

Founded in 1914 and part of the J.M. Huber Corporation since 2016, Martinswerk is one of the leading manufacturers of halogen-free fire retardants and specialty material solutions. Martinswerk produces more than 100 specialty products based on aluminum hydroxide and aluminum oxide plus organic matting agents and carriers. Martinswerk products increase safety and performance with specialty additives for polymers, paper and coatings and advanced products for the ceramics, refractories, polishing and agricultural industries.

About up to data

up to data, founded in 1992, is an experienced provider of innovative and customizable IT solutions focusing on Laboratory Information Management Systems (LIMS) for various industries and company sizes.

The company's core LIMS product is up2LIMS, based on Thermo Scientific™ SampleManager LIMS™. As a leading implementation partner and reseller of Thermo Scientific™, the up2LIMS team guides customers from the pharmaceutical and chemical industries as well as contract and QC laboratories through the entire LIMS lifecycle, offering services from conception and customization to long-term system support.

The LIMS solutions are specifically designed to meet current industry regulations, including GMP, ISO 17025, and FDA 21 CFR Part 11. The company's quality management system is certified by DQS following the standard for DIN EN ISO 9001:2015. Through long-term partnerships with industry leaders, up to data ensures that its solutions support the latest technologies while meeting the individual requirements of laboratories optimally.

Our digitalization solutions integrate seamlessly into existing laboratory environments and support the specific processes of, for example, QC laboratories, analytical service laboratories, and production laboratories. Through automated workflows, throughput times are optimized, thereby significantly increasing laboratory efficiency.